Mold Manufacturing Industry

Total

4

-

These larger-sized machines are designed for heavy load grinding to improve performance, precision and stability for highly accurate workpieces along with finer finishes. A number of components contribute to a single-piece design, rigid machine structure that minimizes vibration and displacement. They include: heavy-duty double-V guideway, a double-hydraulic cylinder and a base under the machine table that is long enough to support the full travel of the table.

-

For the requirements of high precision and surface roughness required in mold industry, Chevalier provide FSG-1632ADIV Fully Automatic Precision Surface Grinder. iSurface control's data sets the in-machine dynamic balancing function to reduce the grinding wheel vibration and eliminating the workpiece surface ripple to improve grinding quality. Surface grinding processing is suitable for various high precision stamping molds that require good surface roughness and flatness.

-

SMART-B1224IV CNC grinders. enhances the performance of Chevalier CNC grinders. Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

-

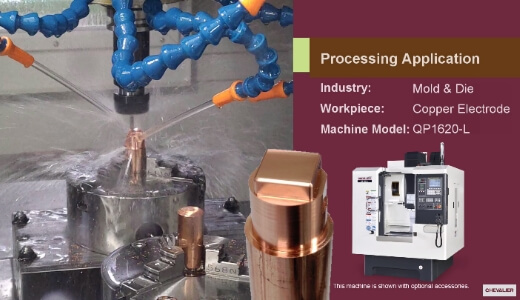

QP1620-L, The stable and fast cutting capability of this series of models meets the high productivity demands. These machines have high machining efficiency and can satisfy the processing requirements of large quantities with shorter cycle time demands.