Grinding Machine

-

Chevalier’s FSG-20/24ADIV CNC surface grinders now include four new machine sizes along with several newly designed features:

- a highly rigid, double-layer structure design with traveling column to further reduce vibration and achieve higher accuracy;

- fully supported design of worktable and maximum table speed 30 m/min, increase processing efficiency;

- an integrated, machine-body, temperature control system greatly improves the accuracy and stability;

- oil-film, orbital lubrication, double-V guideway for smooth, stable longitudinal movements;

- a spindle that can withstand heavy load grinding, optional 18.5 kW spindle motor.

These features are all integrated to provide heavy load grinding to greatly improve grinding performance, precision and stability.

-

This machine is used in the medical, automotive, mining, semiconductor, aerospace and job shop industries. FMG-B1224 meets current and future market needs for factory automation.

-

FMG-B1224AWC|Machine introduction

High Efficiency Traveling Column Precision Profile Grinder- Automatic diamond roller change module

- Automatic wheel change module

-

These surface grinders shorten processing and non-processing preparation while delivering high-precision workpieces. This series has several functions not found on such affordable machines: iSurface control, variable speed spindle, constant surface speed, loading detection and in-machine, manual dynamic balancing.

-

This series is designed specifically for the grinding of complex workpieces. By selecting corresponding accessories, fixtures and customized configurations for automation, it can enhance performance, precision, and stability to meet the demand of stringent quality requirements.

-

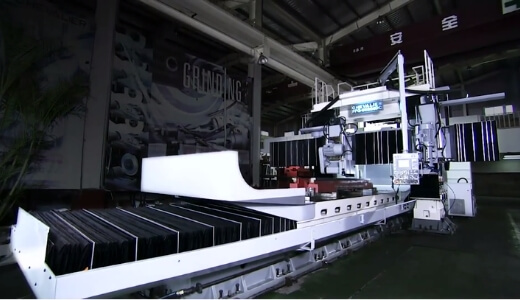

Easy Set Up, Programming and Operation

Chevalier’s FSG-DC Series stands out as the number one choice for fixed-beam, double column grinders for a variety of important reasons, including: an easy-to-use interface, full CNC user-friendly control system, full workpiece capacity, rigidity and accuracy of the dual column design—all features that offer impressive performance. They’re the standards required by the automobile, die and mold, transmission component, electronics, aerospace, and related component machining industries in order to meet current and future market needs and pave the way for factory automation.

-

Mass Production for Small-and Medium-sized Workpieces

Equipped with the latest technology, Chevalier’s FDG-700 is loaded with features that make the innovative double-sided grinder the ideal machine for a variety of flat, hard and brittle materials.

The FDG-700 is perfect for mass production of small- and medium-sized workpieces that demand high-precision and high efficiency with an eight-stage pressure control. This fine grinding process offers several advantages in flatness, parallelism, surface finish and size tolerances.

The FDG-700 features Chevalier's iSurfaceDS, a PC-based control that makes it possible to intuitively operate the grinder entirely by conversational graphic control.

The machine features a high-precision, digitally controlled pneumatic system that automatically adjusts according to the selected pressure. The high-precision, contact-measuring system includes grinding height control and dressing monitoring.

-

Easy Set Up, Programming and Operation

Chevalier’s FSG-DC Series stands out as the number one choice for fixed-beam, double column grinders for a variety of important reasons, including: an easy-to-use interface, full CNC user-friendly control system, full workpiece capacity, rigidity and accuracy of the dual column design—all features that offer impressive performance. They’re the standards required by the automobile, die and mold, transmission component, electronics, aerospace, and related component machining industries in order to meet current and future market needs and pave the way for factory automation.

-

Multi-Functional CNC Surface Grinder - Many SMART users in various industries, including the medical, automotive, mining, semiconductor, aerospace and job shops, have experienced a dramatic increase in reliability and productivity.

-

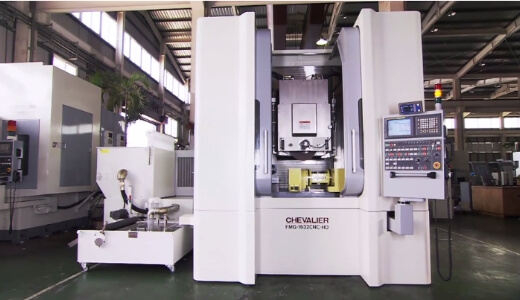

FMG-1632CNC-HD is a high-precision, multi-axis, servo-driven, movable column machine designed for powerful CNC grinding. It is very suitable for forming and grinding various complex shapes and difficult-to-grind materials.

-

The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.