Grinding Machine

-

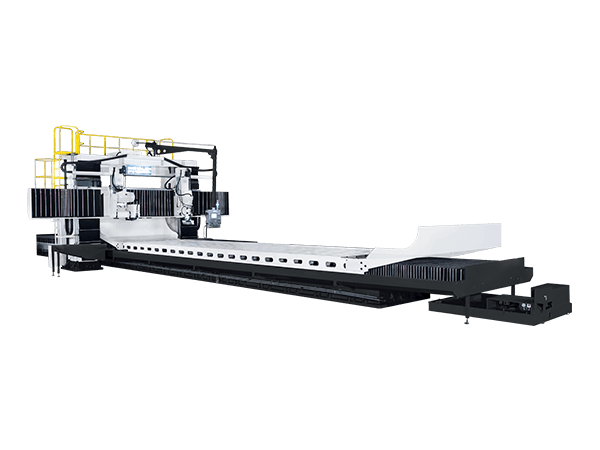

Chevalier's FPG-DC series moving-beam double column grinder is specifically engineered to meet the growing demand of large, high-precision workpieces for industries such as automotive, aerospace, energy, shipbuilding, rail transportation, machine tools, and defense. This series features patented square-type ground beam, an ultra-wide door gantry, and a double “V” longitudinal guideways, offering significant structural advantages. It is equipped with full CNC user-friendly control system, ensuring high production efficiency and product quality, making it an essential and irreplaceable piece of equipment in modern manufacturing processes.

-

FMG-B12/16 Series grinding machines are designed to be user friendly. Now, our exclusive next generation SMART iControl incorporates production efficiency, which simplifies operation procedures and greatly enhances the performance of Chevalier CNC grinders. Combined with TaskLink+, it allows operators to easily create their own programs for generating complex grinding tasks in a single cycle.

-

FMG-1632CNC-HD is a high-precision, multi-axis, servo-driven, movable column machine designed for powerful CNC grinding. It is very suitable for forming and grinding various complex shapes and difficult-to-grind materials.

-

The SMART iControl, standard with the four largest machines in our FSG-60DC+VH Series, features conversational programming and human-machine interface (HMI).Combined with TaskLink+, it allows operators to easily create their own programs for generating complex grinding tasks in a single cycle.

-

The double column grinders of easy-to-operate grinding machines includes our exclusive iSurface control, standard with FSG-40, 50 and 60 series. The fully automatic control delivers constant surface speed in dressing and grinding cycles; and smart grinding path function for a higher level of precision, flexibility and functionality.

-

This series is well suited for mechanical metal processing, which is widely used in the punch industry, with its assortment of shapes and specifications. The graphical conversational software for this machine is a perfect match for this industry’s small batch production needs.

-

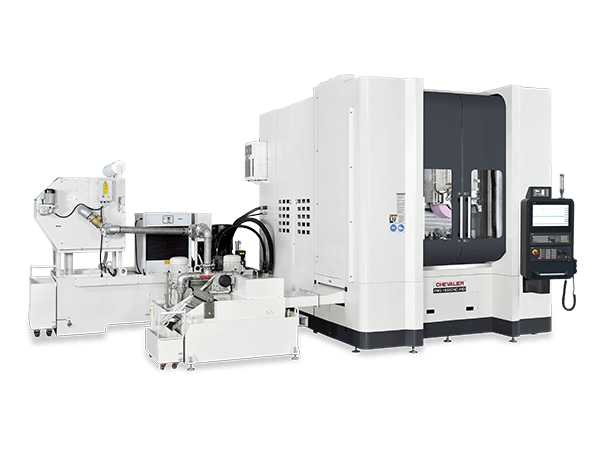

Chevalier SMART- H/B818IV grinding machines are designed to be user friendly. This series is designed specifically for the grinding of complex workpieces. By selecting corresponding accessories, fixtures and customized configurations for automation, it can enhance performance, precision, and stability to meet the demand of stringent quality requirements.

-

This series is designed specifically for the grinding of complex workpieces. By selecting corresponding accessories, fixtures and customized configurations for automation, it can enhance performance, precision, and stability to meet the demand of stringent quality requirements.

-

Chevalier adds the new FRG-400/600 Series of rotary surface grinders to our excellent family. The series has several design features that ensure smooth, stable grinding: a durable, ribbed machine column structure that can withstand heavy-load grinding with a fully enclosed hydrostatic rotary table.

The series grinders increase efficiency and productivity for such industries as aerospace, automotive, energy, medical and semiconductor in order to meet current and future market demands.

-

Chevalier adds the new FRG-400S/600S Series of rotary surface grinders to our excellent family. The series has several design features that ensure smooth, stable grinding: a durable, ribbed machine column structure that can withstand heavy-load grinding with a fully enclosed hydrostatic rotary table.

The series grinders increase efficiency and productivity for such industries as aerospace, automotive, energy, medical and semiconductor in order to meet current and future market demands.

-

Chevalier’s SMART-H/B20/24IV Series larger machine size is designed for heavy loads to achieve higher accuracy and performance in finer workpiece finishes.

-

Chevalier’s FSG-20/24ADIV CNC surface grinders now include four new machine sizes along with several newly designed features:

- a highly rigid, double-layer structure design with traveling column to further reduce vibration and achieve higher accuracy;

- fully supported design of worktable and maximum table speed 30 m/min, increase processing efficiency;

- an integrated, machine-body, temperature control system greatly improves the accuracy and stability;

- oil-film, orbital lubrication, double-V guideway for smooth, stable longitudinal movements;

- a spindle that can withstand heavy load grinding, optional 18.5 kW spindle motor.

These features are all integrated to provide heavy load grinding to greatly improve grinding performance, precision and stability.